Summary of fixing options available for cast iron seats

| K2 | K2T | K4 | K4T | K5 | K5C | K5T | K11 | K11C | K11T | K12 | K16T | K17T | K18T | |

| Georgian Seat | ||||||||||||||

| Victoria Seat | ||||||||||||||

| Grafton Seat |

Installation Recommendations

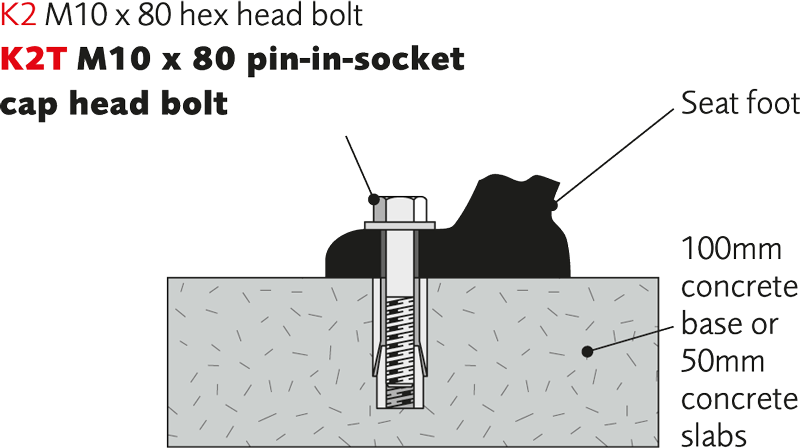

Seats can be rawl bolted to an existing surface of sound concrete, or well laid traditional size concrete or stone slabs, using these M10 x 80 rawl bolts. This method enables seats to be moved, should the need arise, though is not normally suitable for installing seats onto small block paviours.

All the bolts in these options are stainless steel.

- K2 have hex head bolts

- K2T have tamper resistant pin-in-socket socket cap head bolts to reduce the risk of unauthorised removal

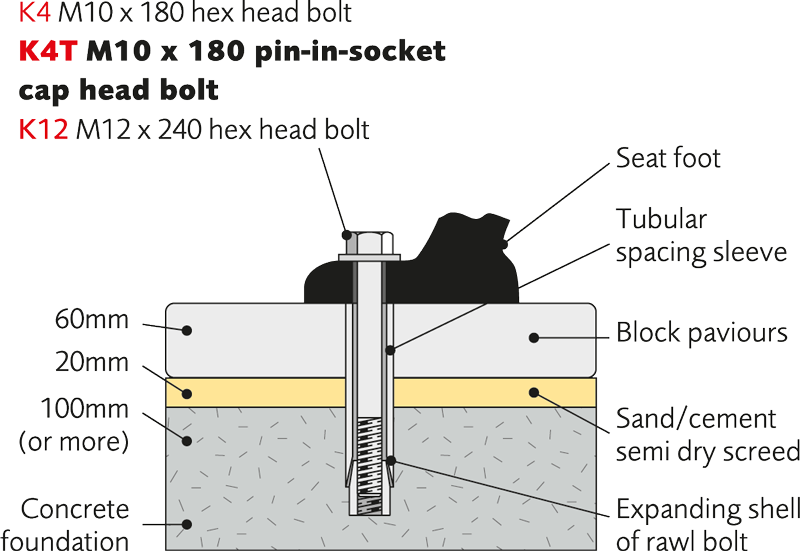

For the installation of seats (which might need to be removed), on small block paviours, typically 60mm thick, we recommend either the K4 or K4T rawl bolts, or K12 extended rawl bolts, with semi collapsible spacing tubes.

The spacing tubes hold the rawl bolt shell in the concrete (which must be laid beneath the paviours) whilst the bolt is being tightened. It is recommended that the paviours in the area of the seat are bedded on top of the concrete using a semi dry sand cement screed about 20mm thick.

These kits are also suitable for fixing seats onto surfaces of bituminous macadam, laid on top of concrete.

All the bolts in these options are stainless steel.

The K4 options are 180mm long, and the K12 option is 240mm long.

- K4 and K12 have hex head bolts

- K4T have tamper resistant pin-in-socket socket cap head bolts to reduce the risk of unauthorised removal

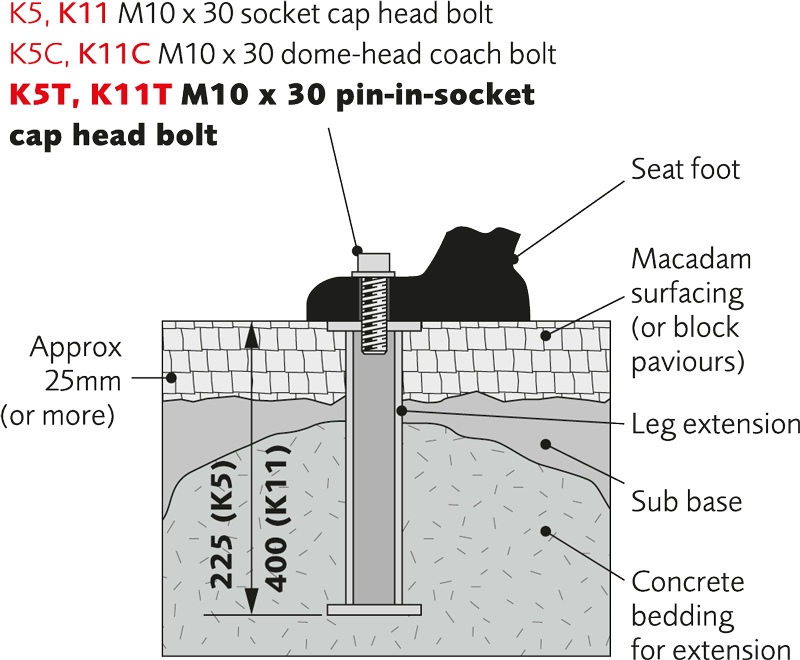

These extensions have the advantage of offering a very strong and permanent installation, though they are more work than the K2 or K4 fixing kits.

This means of fixing is suitable for grassed areas, small block paviours and macadam surfaces. The extensions are bolted to the feet of the seat and then accurately positioned in the concrete bedding, using the seat as a template.

After the concrete securing the extensions has set, the seat is removed, and the final surface is laid to the tops of the extensions. The seat is then returned to the site and finally bolted down.

All the bolts in these options are stainless steel.

The K5 options are 225mm long, and the K11 options are 400mm long.

- K5 and K11 have socket cap head bolts.

- K5C and K11C have coach bolts (which are very tamper resistant, but difficult to remove if ever the seat needs to be moved).

- K5T and K11T have tamper resistant pin-in-socket socket cap head bolts to reduce the risk of unauthorised removal.

These 225mm extensions have been specially designed for locations where cast iron seats need to be regularly removed, such as sea front promenades or streets where markets are held.

After the seats have been removed the tamper resistant pin-in-socket cap head bolts are returned to the threaded holes, which are recessed into the ground fixings, to prevent them filling with dirt.

After replacement they are flush with the ground, so nothing protrudes to trip over when the seats have been removed.

The ground fixings have 12mm of M10 internal thread, so the threads will not easily strip, and are suitable for many years’ use. Care must be taken not to cross thread the bolts, and to grease the threads during every installation.

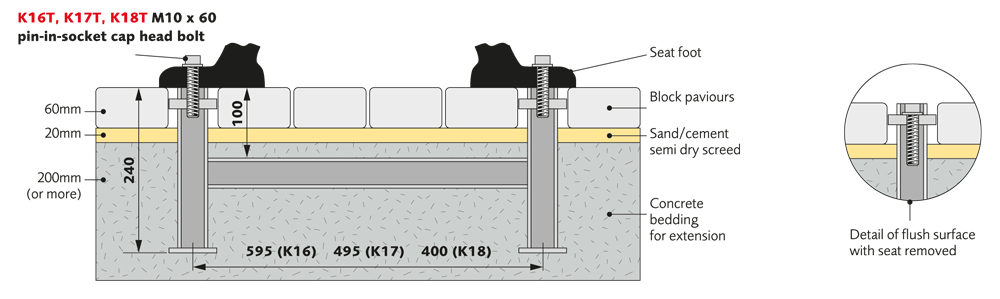

All the bolts in these options are stainless steel.

- K16 and K16T are for the Victorian seat

- K17 and K17T are for the Georgian seat

- K18 and K18T are for the Grafton seat